Szanowni Państwo, informujemy iż od dnia 21.04.2025 zmieni się lokalizacja Oddziału Koszalin.

Read more ...

Inwestuj w maszyny – my znajdziemy fundusze! Chcesz kupić maszyny od RYWAL-RHC? Dzięki DUE ...

Read more ... Międzynarodowe Targi Spawalnicze ExpoWelding 2024 w Katowicach były dla naszej firmy wyjątkowym wydarzeniem, które umożliwiło nam zaprezentowanie innowacyjnych rozwiązań oraz nawiązanie nowych, wartościowych relacji z klientami i partnerami biznesowymi.

Międzynarodowe Targi Spawalnicze ExpoWelding 2024 w Katowicach były dla naszej firmy wyjątkowym wydarzeniem, które umożliwiło nam zaprezentowanie innowacyjnych rozwiązań oraz nawiązanie nowych, wartościowych relacji z klientami i partnerami biznesowymi.

Under GOLD brand you can find many high quality welding consumables.

Read more ...

Our own brand, designed especially for welding industry. High quality for reasonable prcies.

Read more ...We are a producer of high quality welding consumables and abrasive materials at reasonable price. We also own a bandsaws blades welding manufactury.

Please feel free to contact us.

Approvals: MOST SG2 ITS TÜV, DB, GL, DNV, PRS MOST SG3 ITM TÜV, DB, DNV, PRS

Offer: Bandsaw blades of various parameters for all kinds of band saws.

Offer: Abrasive materials of all kinds and destination.

See all

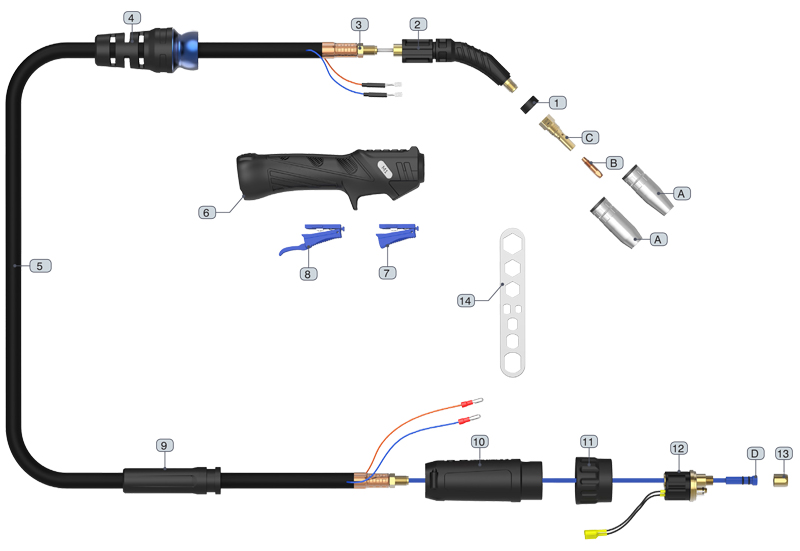

• 20% lighter - After a long day’s work you really will feel the difference.

• Perfect Balance - A great tool for all day welding and ideal for positional welds.

• SIC Technology - Spatter created by the arc is contained with in a patented chamber that collects the molten metal droplets.

• Damage Resistant Necks - Armour plated so it can stand the knocks.

| Technical Data IEC/EN 60974-7 | M1 MOST |

| Cooling Method | Air-Cooled |

| Ratings | |

| CO2 | 180 A |

| Mixed Gas M21 | 150 A |

| Duty cycle | 60% |

| Wire Size | 0,6-1,0 mm |

| Length / Catalogue No. |

(3 m) 55 08 305080 (4 m) 55 08 305081 (5 m) 55 08 305082 |

| Lp. | Item | Cataloque No |

| A | Conical nozzle M1 Ø12 | 55 13 000730 |

| Conical nozzle M1 Ø10,5 | 55 13 000731 | |

| B | Contact tip M1 M6 | |

| C | Contact tip holder M1 | 55 13 003873 |

| D | Wire liner | |

| 1 | Insulator M1 | 55 13 003870 |

| 2 | Swanneck M1 | 55 13 014570 |

| 3 | Lock nut | 55 13 004309 |

| 4 | Cable support | 55 13 006872 |

| 5 | Outer liner assembly M1 3 m | 55 13 016102 |

| Outer liner assembly M1 4 m | 55 13 016103 | |

| Outer liner assembly M1 5 m | 55 13 016104 | |

| 6 | Handle | 55 13 006661 |

| 7 | Microswitch standard trigger assembly | 55 13 006675 |

| 8 | Microswitch extended trigger assembly | 55 13 006676 |

| 9 | Cable support | 55 13 006835 |

| 10 | Housing assembly | 55 13 006689 |

| 11 | Gun plug nut | 55 13 006519 |

| 12 | Euro plug 2 | 55 13 006696 |

| 13 | Liner retaining nut | 55 13 006695 |

| 14 | Wear parts spanner | 55 13 006685 |