Międzynarodowe Targi Spawalnicze ExpoWelding 2024 w Katowicach były dla naszej firmy wyjątkowym wydarzeniem, które umożliwiło nam zaprezentowanie innowacyjnych rozwiązań oraz nawiązanie nowych, wartościowych relacji z klientami i partnerami biznesowymi.

Międzynarodowe Targi Spawalnicze ExpoWelding 2024 w Katowicach były dla naszej firmy wyjątkowym wydarzeniem, które umożliwiło nam zaprezentowanie innowacyjnych rozwiązań oraz nawiązanie nowych, wartościowych relacji z klientami i partnerami biznesowymi.

Nasza spółka zagraniczna RYWAL Romania, miała zaszczyt uczestniczyć w prestiżowych targach Metal Show & TIB, które odbyły się w dniach 14-17 maja 2024 w renomowanym Centrum Wystawienniczym Romexpo w Bukareszcie.

Read more ...

WEARWELL - Platformy robocze Foundation. Sprawdź jakie korzyści przyniesie Tobie stosowanie mobilnych platform.

Read more ...

Under GOLD brand you can find many high quality welding consumables.

Read more ...

Our own brand, designed especially for welding industry. High quality for reasonable prcies.

Read more ...We are a producer of high quality welding consumables and abrasive materials at reasonable price. We also own a bandsaws blades welding manufactury.

Please feel free to contact us.

Approvals: MOST SG2 ITS TÜV, DB, GL, DNV, PRS MOST SG3 ITM TÜV, DB, DNV, PRS

Offer: Bandsaw blades of various parameters for all kinds of band saws.

Offer: Abrasive materials of all kinds and destination.

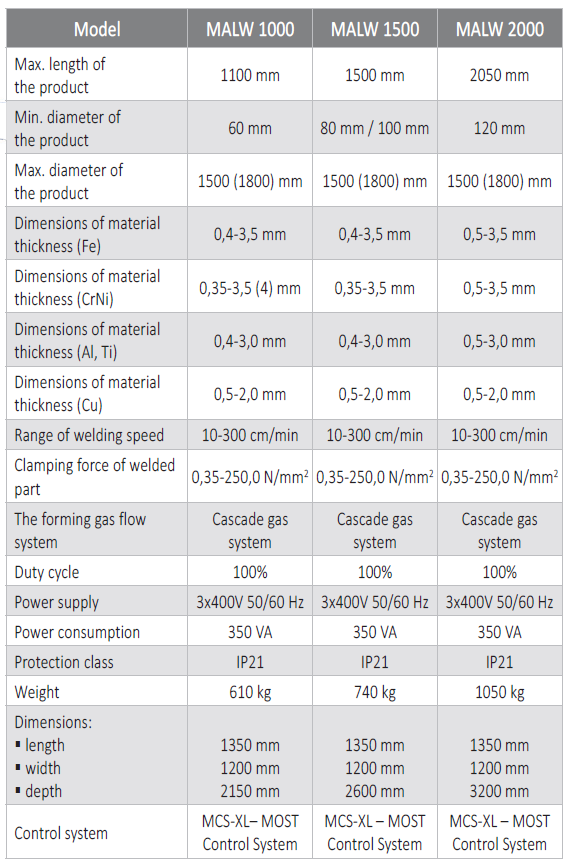

MALW is a modern welding automat of new generation designed for longitudinal welding, which features perfect ergonomics and operating parameters. Maximal length of weldment is 2050 mm, maximal diameter of welded material – 1500 mm, thickness of material in range of 0,5-3,5 mm. the detailed mechanical construction, electronics, drivers of the newest generation and highly advanced technologies of TIG DC, TIG AC, Plasma Weld DC, Plasma Weld AC welding methods provide the wide range of applications in welding of all types of steel. The construction of arms is designed as spatial construction, characterized by high flexibility and quality. The overpressure of the work-piece to the welding mandrel is pneumatically through the gear levers, use of copper segments provides the optimal settings and enables to carry off heat precisely from the welding area. The backing sheet is made of the high quality CuCrCz alloy and features the high resistance. The advanced driving system of welding torch is achieved by servomotor and allow the precise positioning with exactness of 0,2 mm, welding speed of 10-300 cm/min and feed of 600 cm/min, what significantly shortens stoppage in welding processes. The gas management system is one of the functions worth mentioning. The gas distribution is realized by three independent systems: the welding torch, the weld cooling and forming gas. The forming gas distribution flow applies the unique cascade system of backing weld protection. Depending on the actual position of torch, the cascade gas flow system split forming gas automatically into sections, with 10 or 15 – out of 80 – holes opened in the same time. This solution greatly reduces the forming gas consumption by 70%. The unit can be equipped with an additional cold wire feeder, what extends the range of its application in thicker sheet welding (e.g. in pressure tanks production and other objects which manufacturing processes that demand the wire application). The unit is provided with the integrated welding fume extraction system, which can be connected to the central filtroventilation system, and the integrated cooling system. The device is controlled by digital control system, which has been designed especially for longitudinal welding automats. Control system has a wide range of functions, by which all requirements of longitudinal welding are solved.

Pipe test:

|

|

|

Tank test:

|

|

|

|