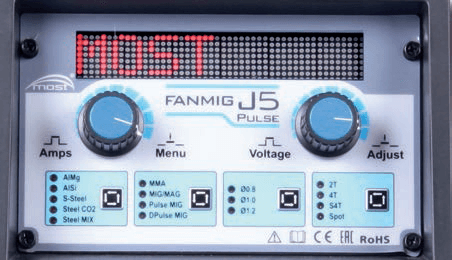

FANMIG J5 Pulse MOST is a modern semi-automatic inverter for MIG/MAG welding. The device is designed for steel and stainless steel welding in shielding gas environment. FANMIG J5 Pulse offers synergic programs for pulse or double-pulse welding of different materials. It can be perfectly used in crafts, car body works, repairs or in hobby works etc. Welding parameter settings are made on machine’s front panel. The parameter value is set with the knob. Confirmation of the

settings is done by pressing the knob. Two synergistic programs are available for welding steel with 0.8 mm and 1.0 mm wire. Depending on the wire diameter selected, the knob changes both the welding current and the corresponding wire feed speed. The device is powered from a single-phase 230 V. The wire feeder enables wire welding using 5 kg/D200 and 1 kg spools. Recommended steel wire diameters: 0.8 - 1.0 mm.

Fanmig J5 Pulse MOST creates a convenient to work and transport set when placed together with the gas cylinder on the WUS HD MOST trolley.

Cooling fan and thermal sensor protect the device against overheating.

Made in accordance with EN 60974-1 standard.

Advantages of FANMIG J5 Pulse MOST:

| Model | FANMIG J5 Pulse MOST |

| Electrical power supply and tolerance | 1x230/ 50-60 V/ Hz ±15% |

| Welding current range |

MIG/MAG: 30-200 A |

| Open circuit voltage U0 | 69 |

| Network protection | 16 A (delayed) |

| Nom. Power consumption S1 (100%) | 8,0 kVA (MMA); 7,7 kVA (MIG/MAG) |

| Duty cycle | MIG/MAG - 200 A (20%) 89 A (100%) MIG/MAG Pulse - 170 A (20%), 76 A (100%) MMA - 180 A (20%), 80 A (100%) |

| Wire feed speed | 1-15 m/min |

| Protection class | IP21S |

| Dimensions | 490x210x410 mm |

| Weight | 13,3 |

| Catalogue No. | 51 00 020195 |

Device assembly:

The device is supplied in a cardboard box with earth cable, a gas hose and user’s manual.

Wire feeder is equipped with standard 0.8-1.0 mm rollers for steel wire (51 13 007833).

Additional welding torches and accessories (optional):